It is vital to completely Examine the accompanying complex components, Procedure manuals, upkeep manuals, attachment Recommendations, computer software package and instructions and hold them correctly, as failure to take action may prevent the device Device from accessing more capabilities and make maintenance hard.

Each CNC machining and 3D printing are exceptional equipment from the arsenal of the engineer. Their exclusive Added benefits make each much more suited for various situations however.

Numerous types of hues can be obtained to create the desired aesthetic. See illustrations in our powder coating finishes gallery.

Running Natural environment for CNC Machine Instrument: For best efficiency, CNC device equipment must be placed in a relentless temperature environment and away from equipment with strong vibrations (which include punches) and machines that generates electromagnetic interference.

Significantly with the external auxiliary equipment: when there is a hydraulic procedure pump station, Test if the amount of hydraulic oil is ample; for anyone with an air force method, regularly drain the air compressor and gasoline storage stress vessel to circumvent excessive dampness from accumulating and moving into the machine Device underneath the pressure of air flow, which may bring read more about corrosion and harm to parts and components.

Concerning functions the mattress along with the toolhead can rotate, supplying usage of the workpiece from a different angle.

Facilitation of modern manufacturing management through the use of electronic information and facts, regular code, and Laptop Management approaches

Tapped holes not explicitly identified as out as Capabilities to the quoted CAD design could possibly be machined to your diameters laid out in that model.

Servicing of the CNC technique when not in use for a lengthy time frame: Consistently electrical power to the CNC system or run the warm-up system.

This machining method is fairly simple and may make products and solutions with a simple construction. Having said that, It's not at all well suited for machining complicated geometries or merchandise with intricate parts.

Ever puzzled how the devices that condition our entire world are made? This informative article explores the very best CNC lathe manufacturers, revealing the insider secrets guiding their cutting-edge technology and world wide influence. Find out…

CNC lathes have the bottom cost per unit, but are only suited to aspect geometries with rotational symmetry.

The spindle axis on the machining center is positioned perpendicular on the workbench. The machine has a sizable, portal-style frame consisting of double columns along with a major beam. The double columns are joined by a central beam, making it perfect for processing big and complexly shaped workpieces.

When used that has a Resource magazine on the machining center, they are able to enable continual processing of various processes on one device, decreasing the turnover time between semi-concluded merchandise processes, and therefore growing efficiency.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Tahj Mowry Then & Now!

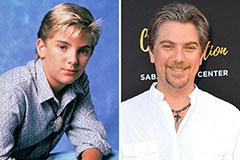

Tahj Mowry Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!